Get in Touch Now!

Or Call Us Now!

087 152 0277

Our Garage Door Springs Repairs & Installation Services

We service the entire Gauteng and Pretoria area.

- 24 Hour Emergency Service

- Same Day Repair Service ( We are in your area)

- We Use Affordable Quality & Trusted Brands

Garage Door Spring Repairs & Installations Johannesburg

Garage doors are quite huge and of massive weight; with the help of garage door springs, these can be opened and closed without any difficulty. The springs need to be designed with the force of the doors so that they can be

pulled against the door. With this basic design in mind, the garage door springs are designed in a turning or stretching pattern for providing the right balance. Garage door springs are broadly classified into two main categories – torsion springs and extension springs. Here is a brief overview of each of these categories:

Torsion Springs

If you are looking for springs to balance garage doors that weigh anywhere between 45 and 210kg, torsion springs are a good choice for you. These springs can be used to open & close single as well as double garage doors, with the utmost ease. In this pattern, the springs are coiled and bound very closely to each other.

Call Us

The coils may separate when you try to pull the ends of the torsion springs away; however, once you release your hold, the coils get wound back together again. These springs work because of the twisting pattern of the coils. The mechanical energy in the coils helps to open & close the garage doors. When the coils are un-twisted, the intensity of the force that is released in the reverse direction depends on the amount of twisting that was there on the coils.

The springs that are coiled and wound close together are mounted on the torsion pipe, also known as the shaft. Cable drums can be found at the ends of this steel shaft. Every twisted spring has a cone each on both its sides. Out of these two cones, one is the winding cone and the other is the stationary cone. The spring diameter is seen in the former, while the latter is what we mount on a bracket.

Every garage door has a frame, which we sometimes address as the center bearing plate. The bracket is attached above the center of this plate. The torsion pipe or the shaft is then mounted on the header wall, which is right above the garage door. The twisted springs are extended all along this pipe. The pipe balances well, thanks to the three levels of support it receives from the frame and the bearing plates at both the ends of the walls.

The lowest door panel of the garage is the place where the cables are finally attached to make the opening & closing of the doors easy. These cables align the movement of the doors with the twisting of the springs. The cable drums are the accessories that hold these tightly-wound cables around them. Thanks to the tension produced on these drums, the movement of the garage door is eased.

On the winding cone, you will find holes placed strategically at every 90-degree position for securing the springs and the two-set screws to the pipe. At the bottom of the doors, you will find cables made from steel that run all the way from the roller brackets at the bottom corners till the cable drums, where these cables end up in a notch. The lifting of the door causes the removal of the tension at the drums and unwinding of these springs. So, when the shaft turns, the door is lifted.

The movement of the shaft causes the winding of the cables around the cable drums and the turning of the cable drums as well. When you lower the garage door, these cables unwind and the springs get back to full tension mode. These torsion springs are very useful, as their life expectancy is about 10000 cycles. This means, these springs can last for about 3 to 7 years, if they are taken care of properly.

However, if you increase the weight of the garage door, by adding glass or insulation to it, you are creating undue pressure on the springs. Therefore, the lifespan of these garage door springs gets reduced. The steel shaft & springs are prone to wear & tear, as it experiences a lot of force & tension every time the garage door is opened or closed. Therefore, regardless of how hard the metal is, you will notice cracks, breaks and signs of steel fatigue in this metal when you use these springs for a very long time.

When you want to replace or repair garage door springs, you should never do it yourself. Instead, you need to entrust this service to a professional company such as Garage Door Repairs Johannesburg for the same.

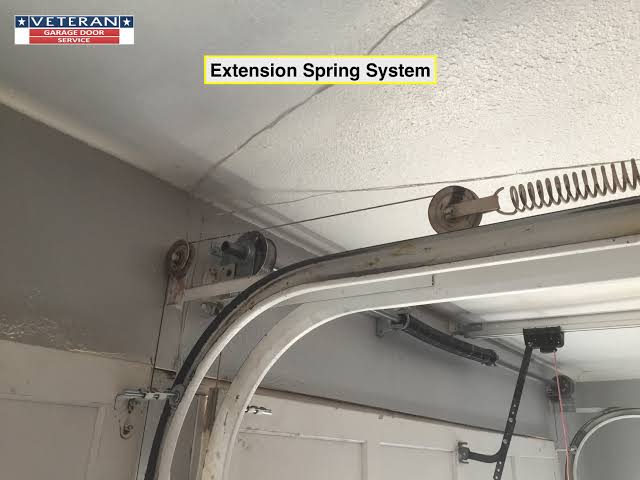

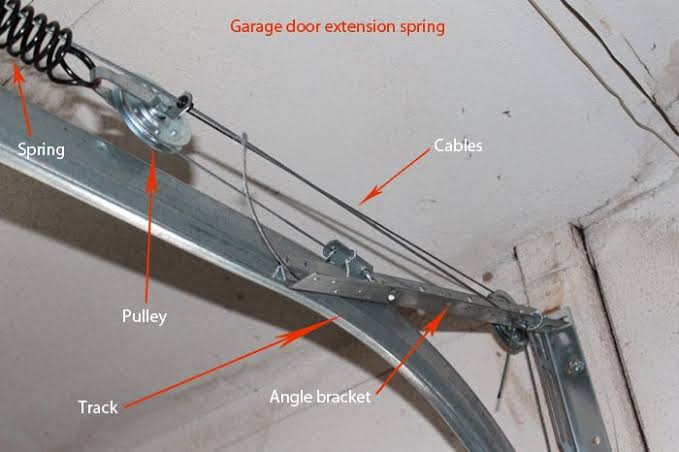

Extension Springs

The extension springs are suitable for garage doors that weigh up to 75kg, which makes them suitable to be used with single garage doors only. These springs are mounted on the sides of the track

found on the upper garage door. These springs use pulley wheels to open & close garage doors. Though, there is only one spring on each side of the track mostly, you may notice doors with more springs, too.

When you close the garage door to lift it easily, these springs come under tension and make the process easier than you imagined. When they use pulley wheels, their functionality is similar to torsion springs. To get the most of these springs, you should remember to choose the right weight that is in line with the weight and height of your garage doors. More often than not, these springs get damaged, when their height & weight don’t match with the doors.

When the door is lifted, it results in a movement of the cables from the stationary pulleys to the second pulleys and winds around them. While they are effective, they aren’t as strong as the torsion springs. As in the case of torsion springs, always consult a professional like Garage Door Repairs Johannesburg. Garage for repairing garage door springs, to get your work done smoothly & safely.

Safety Cables & Replacement

Safety cables are very helpful, in that, they prevent damages and injuries in the event of a spring breaking. Since they are prone to a lot of tension, springs can break anytime, causing damage to people or things in their path. The safety cables run through these springs, thereby protecting the springs.

It is important to check your garage doors regularly and monitor the health of the garage door springs. Since they are opened & closed multiple times, springs can get damaged, or they may have reached their maximum lifespan. Get a professional to examine these springs to see if they can be repaired or replaced

Get in touch with South Africa's most trusted and reliable

garage door repair specialists

Contact Your local garage door repair and replacement experts in Gauteng & Pretoria Today!

Menu

- Home Page

- About Us

- Contact Us

- Our Services

- Service Areas

Contact Info

- Address: 11th St, Linden, Randburg, Johannesburg, 2104

- Phone: 087 152 0277

- email: info@garage-door-repairs-johannesburg.co.za